Enclosure

The primary role of the telescope enclosure is to safeguard the Telescope Structure and the optics subsystems when the telescope is in its parked position and when environmental conditions exceed operational limits. Furthermore, the enclosure is responsible for maintaining the telescope's temperature close to the morning air temperature during nighttime, ready for observations to resume.

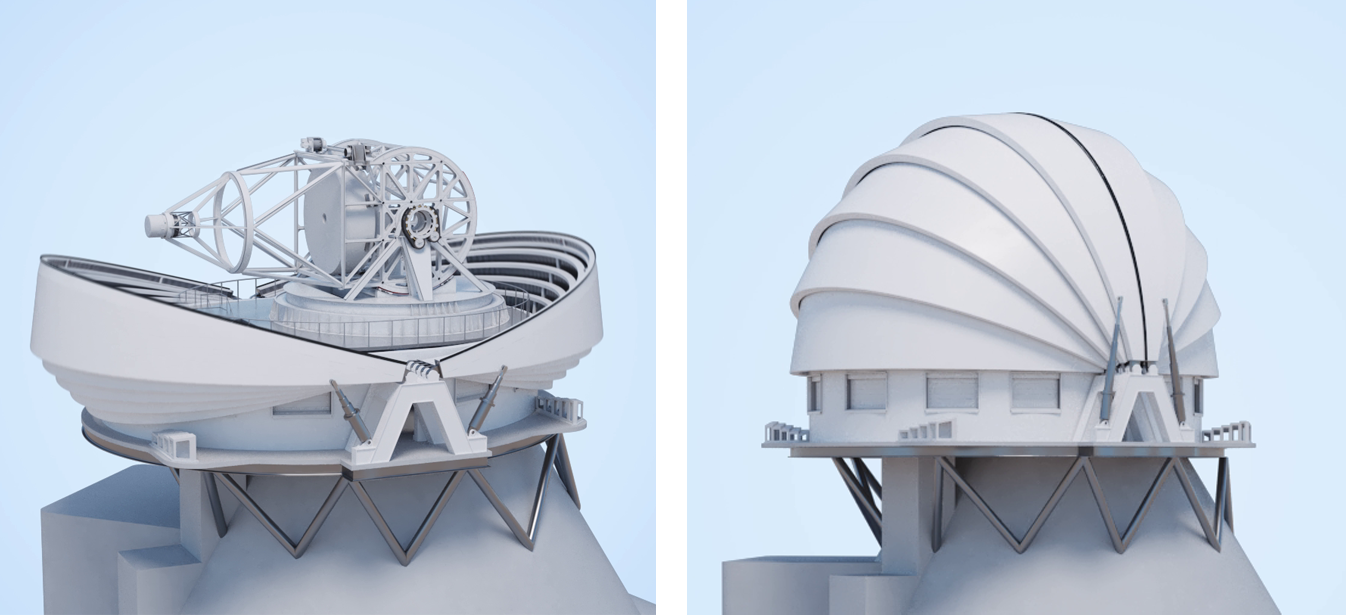

Figure 1. Open enclosure (left) and close enclosure (right)

Figure 1. Open enclosure (left) and close enclosure (right)

The enclosure takes the form of a rigid retractable dome (similar to VTT), designed to facilitate observations in open operation to enhance natural air circulation and achieve optimal seeing performance.

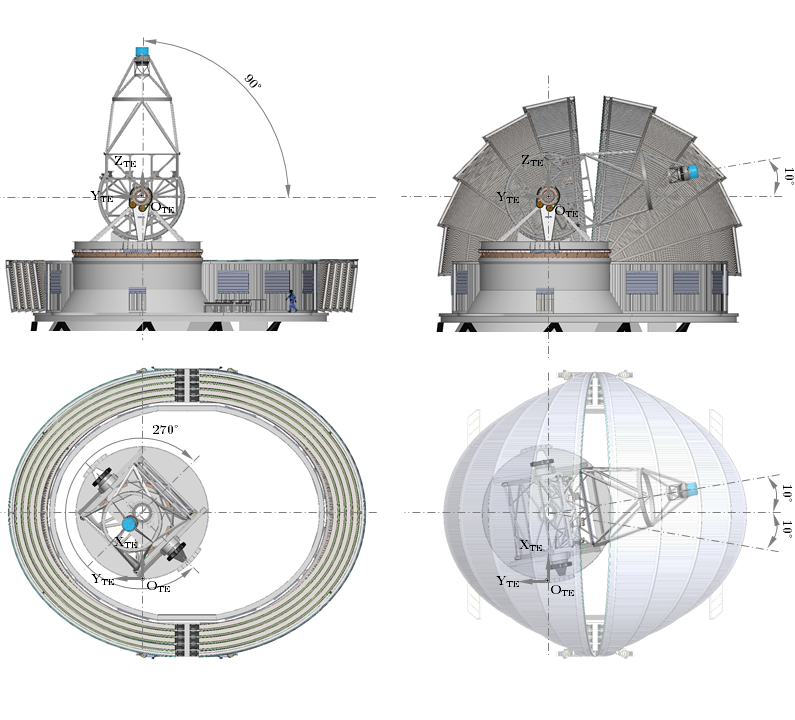

The principal objective of the enclosure's design is to shield the Telescope Structure from adverse environmental conditions when the telescope is not operational. To minimize the platform's size, an elliptical enclosure design has been developed. This arrangement permits the Telescope Structure to execute short movements while the enclosure is closed and is compatible with key maintenance procedures that can be carried out under closed enclosure conditions, notably the maintenance maneuvers for M1 and M2.

Figure 2. EST movement ranges

Figure 2. EST movement ranges

When the enclosure is folded, the segments of the enclosure are positioned entirely below the level of the telescope platform, thereby minimizing disruptions in the airflow over the optical elements.

The enclosure will be operated using four telescopic hydraulic actuators. These actuators will be connected to the two outer segments, and as the enclosure initiates its opening motion, each segment will smoothly guide the next one through a contact region between them.

Several ventilation louvers have been installed on the fixed structure to facilitate natural airflow inside the telescope chamber when the enclosure is closed, thus passively controlling the telescope's temperature in relation to the surrounding environment. An efficient sealing and drainage system has been incorporated to prevent water ingress. A central latching system ensures both structural integrity and a secure seal in the closed configuration. The design is formulated to prevent the accumulation of snow and ice on the enclosure platform.

To guarantee the closure of the enclosure in the event of a hydraulic system failure, a backup system has been incorporated to ensure the enclosure remains closed if the main actuation system fails.

The enclosure's thermal control is achieved through the integration of plate coil solutions within the external segments, which will be directly exposed to solar radiation during observations.